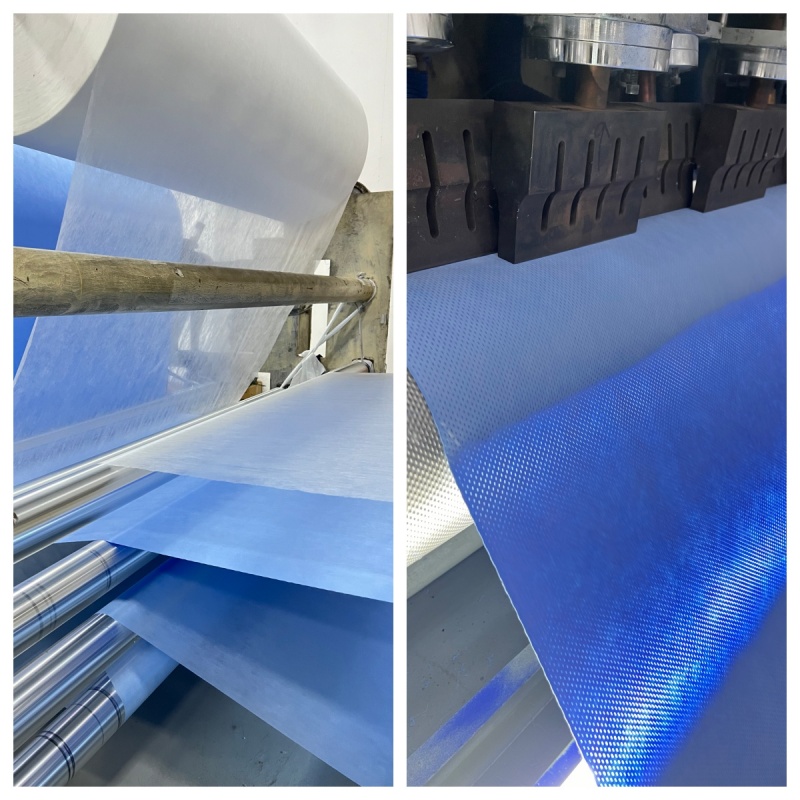

Flexible Multi-Layer Configurations

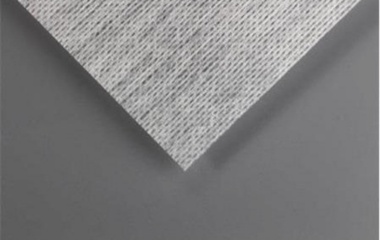

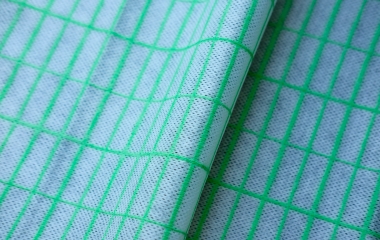

D-TEX’s ultrasonic lamination technology enables the clean and efficient fusion of multiple functional layers without using chemical adhesives. Typical structures include:

- S+M+S — breathable and strong, ideal for filtration and hygiene.

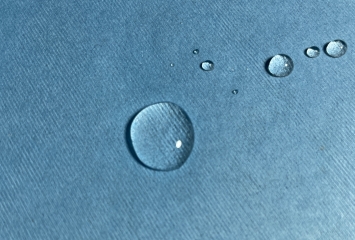

- S+M+PE+S — excellent liquid barrier and strength for protective wear.

- S+PE+S — soft, lightweight, and waterproof for disposable covers.

- M+PE+S — balanced filtration and barrier properties for industrial cleaning.

Depending on the application, the lamination line supports 3-layer, 4-layer, and 5-layer combinations, offering total design flexibility.

Technical Advantages

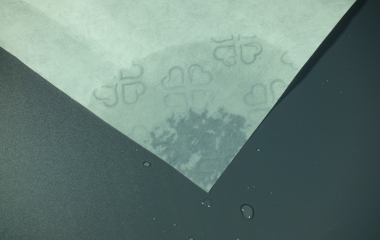

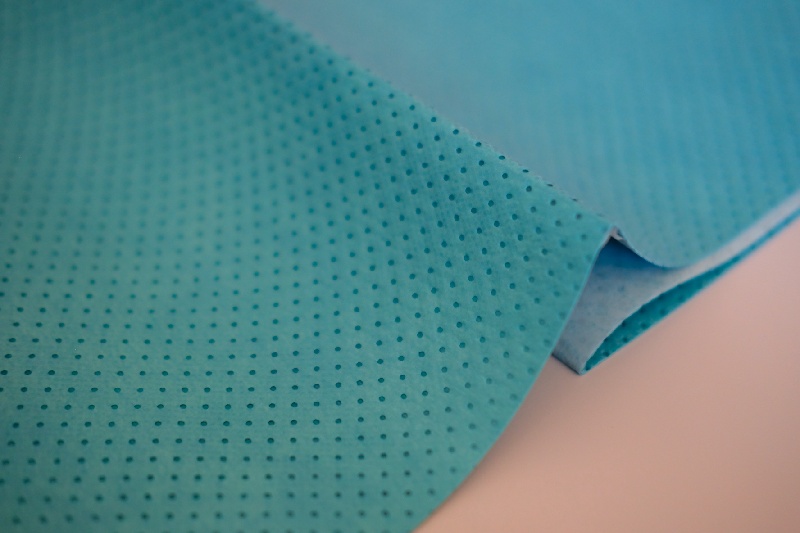

• Ultrasonic Bonding: Heat-free and adhesive-free process ensures clean, consistent bonding without chemical residue.

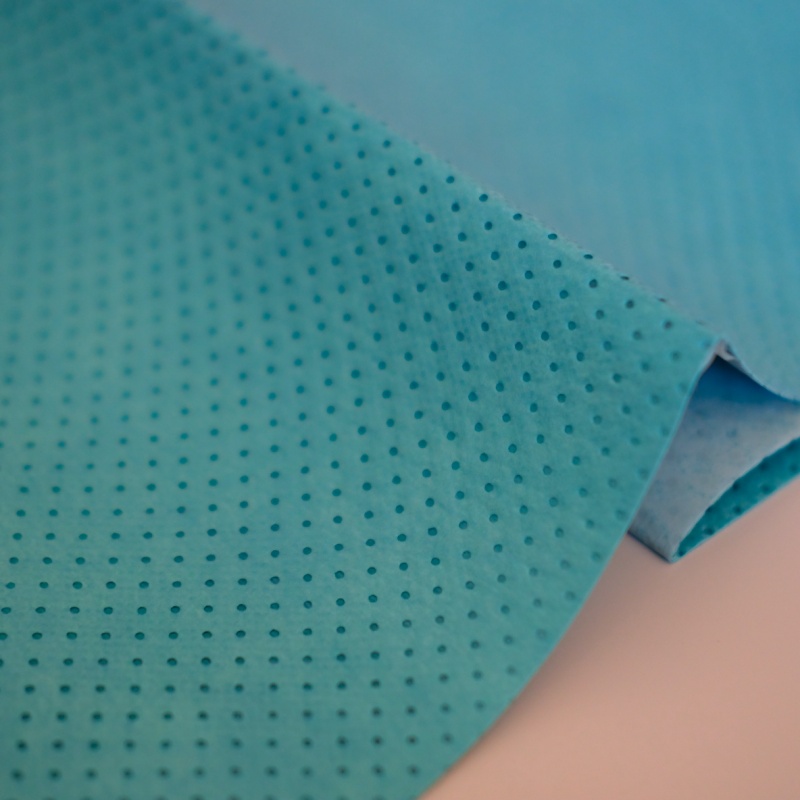

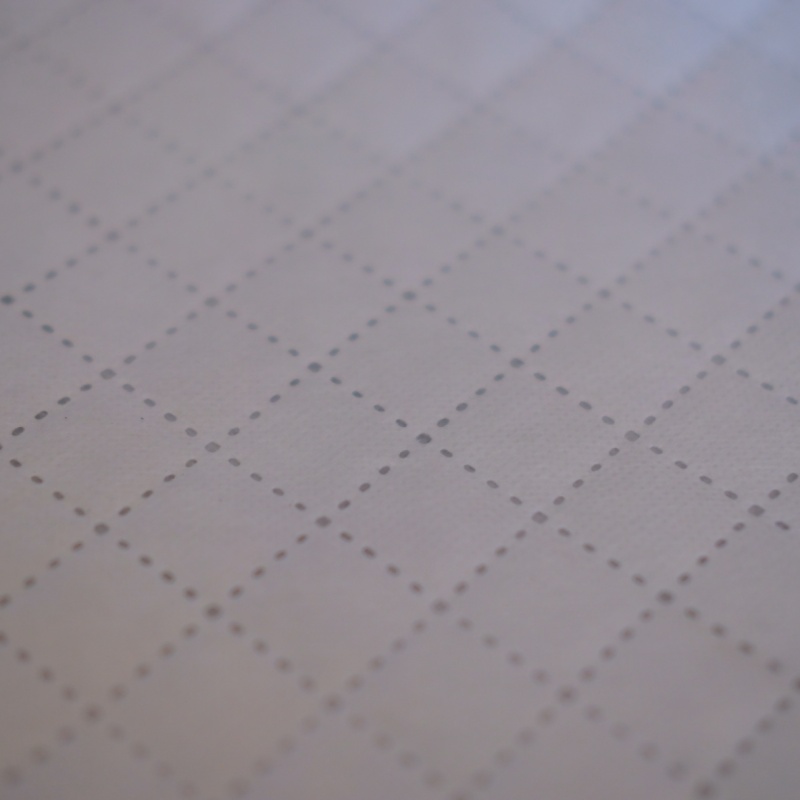

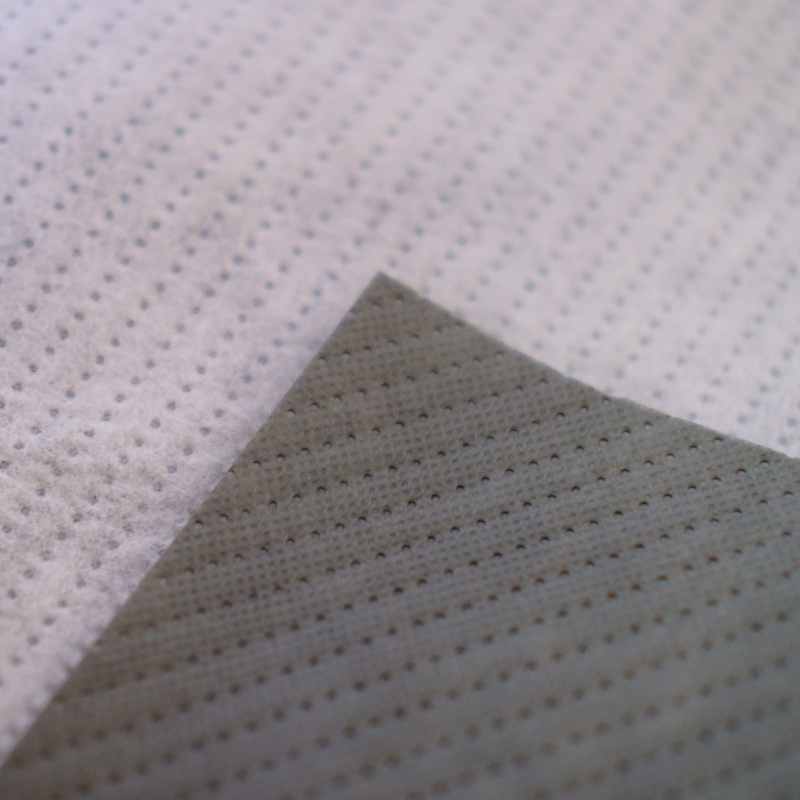

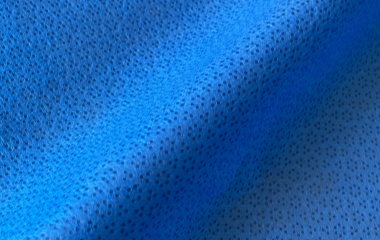

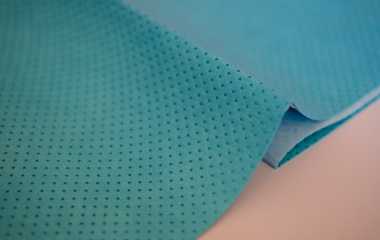

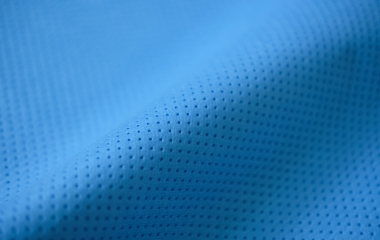

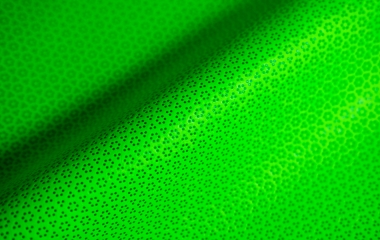

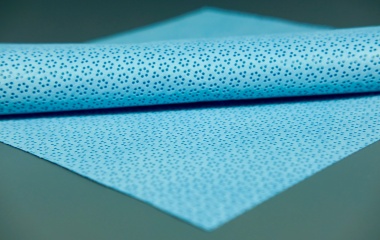

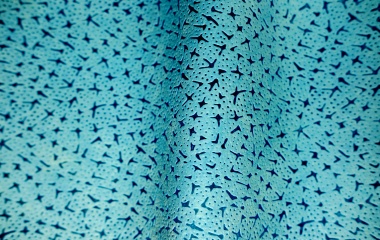

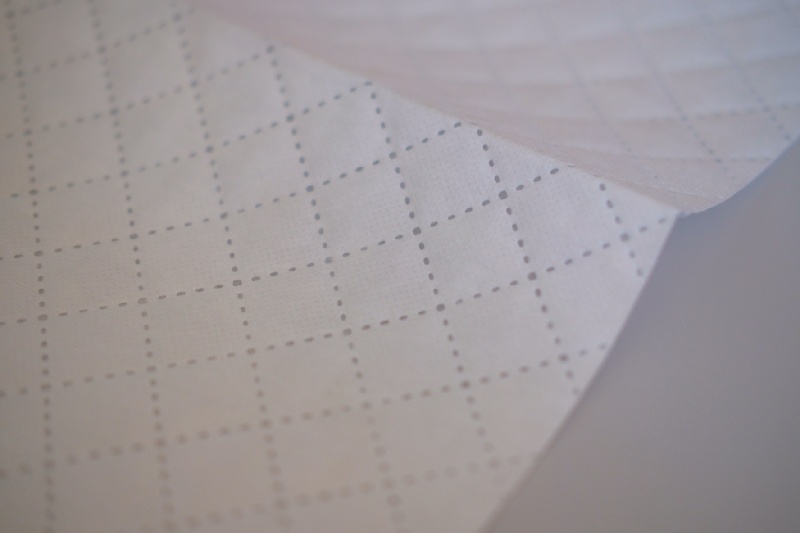

• Uniform Surface Pattern: Dot or diamond embossing improves appearance and bonding strength.

• Stable Mechanical Performance: High tensile strength, tear resistance, and dimensional stability.

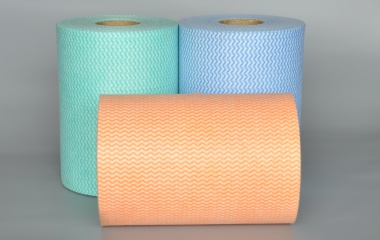

• Customizable Parameters: Basis weight from 25 to 120 gsm, roll width up to 1600 mm, and multi-color options available.

This advanced lamination process enhances the product’s visual quality, cleanliness, and performance uniformity—critical for high-standard industries.

Material Combinations

D-TEX offers versatile material pairing options, including:

- PP spunbond + Meltblown + PE film

- PP spunbond + PP film + Meltblown

- Viscose polyester spunlace + PE film

- Woodpulp polyester spunlace + PP film

Each structure is designed to achieve a specific functional target—such as water resistance, breathability, filtration efficiency, or softness.

Applications

The ultrasonic laminated composites are widely used in:

- Medical protection: Surgical and isolation gowns, drapes, caps, and bed covers.

- Industrial protection: Cleanroom apparel, barrier curtains, and dustproof covers.

- Filtration: Air and liquid filter components, composite filter layers.

- Packaging and hygiene: Protective liners, wrapping, and disposable products.

D-TEX’s production lines ensure stable quality, cleanroom-grade precision, and full traceability from raw materials to finished rolls.

Why Choose D-TEX

• Professional lamination expertise backed by years of nonwoven innovation.

• Flexible production capability supporting both standard and customized structures.

• Technical support and OEM cooperation for global customers in Asia, Europe, and North America.

• Reliable delivery and consistent quality through automated process control.

By integrating spunbond, meltblown, and film technologies, D-TEX delivers composite nonwoven materials that balance functionality, protection, and comfort, making it a trusted partner for global protective and filtration industries.