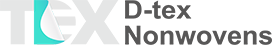

Product Overview

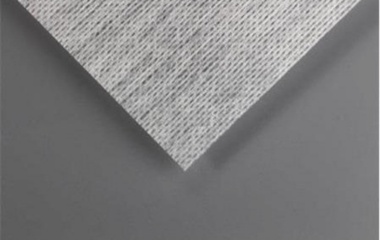

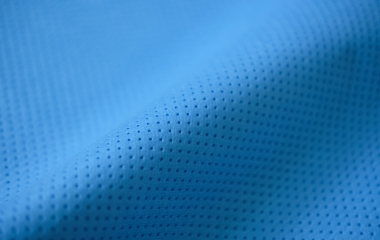

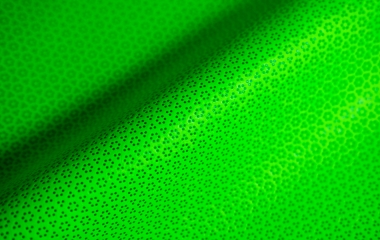

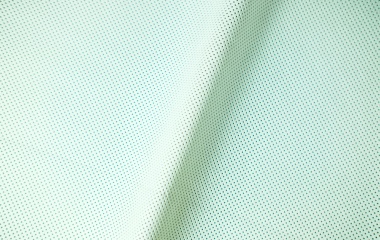

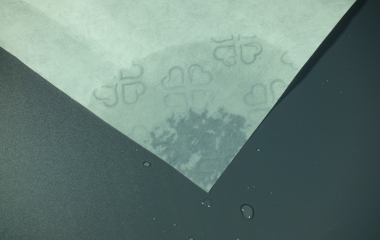

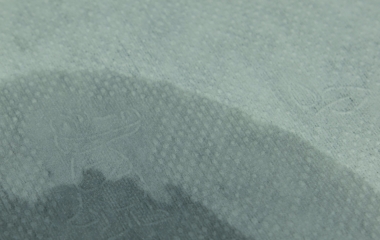

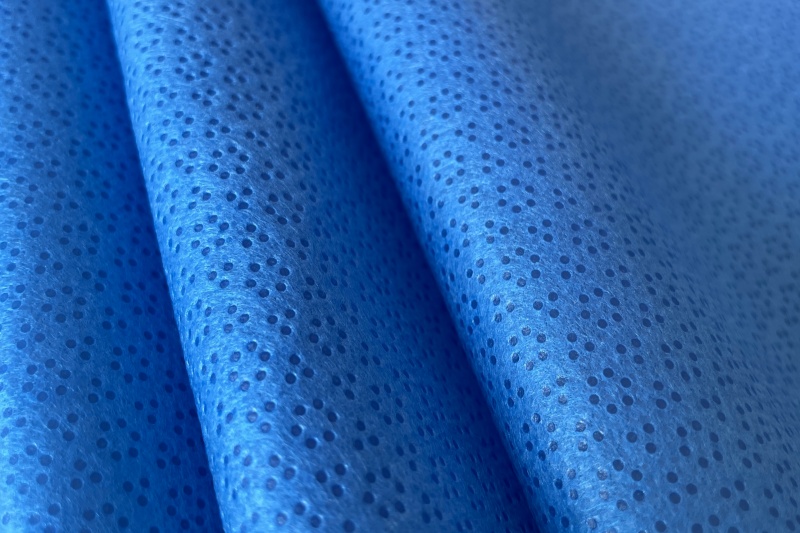

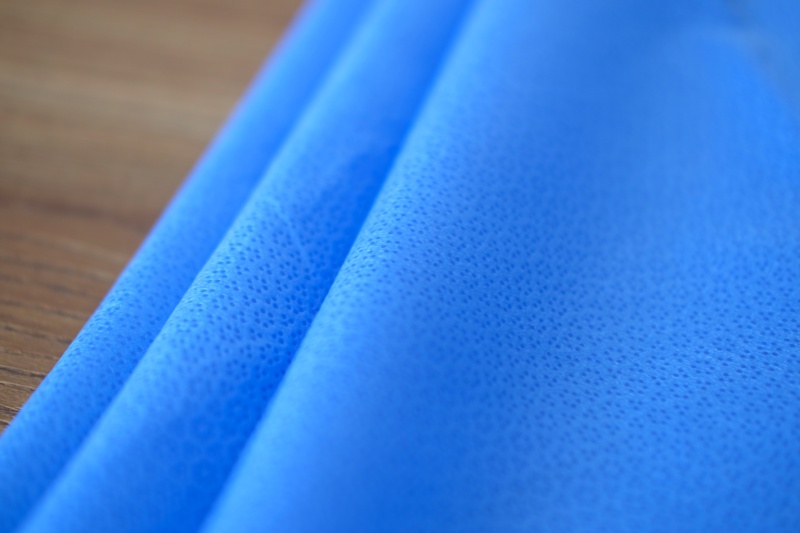

D-TEX SS nonwoven material is a double-layer Spunbond–Spunbond (SS) polypropylene fabric known for its high tensile strength, clean production, and excellent uniformity. With enhanced softness and durability compared to single-layer spunbond, SS material is widely used in medical hygiene, personal care, industrial packaging, and protective applications.

Material Composition

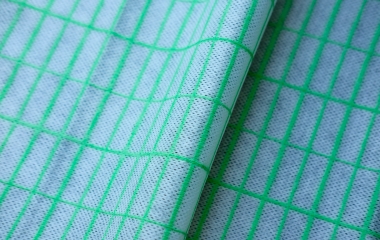

The SS structure is composed of:

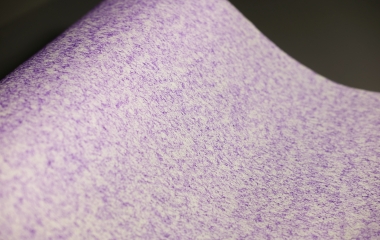

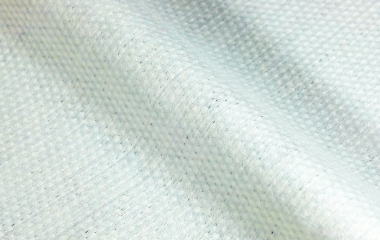

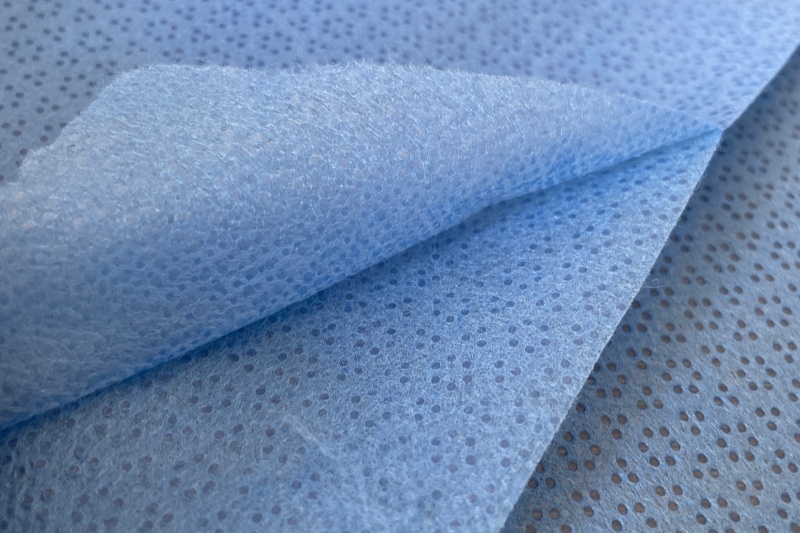

• Two Spunbond (S) layers Produced using continuous polypropylene filaments, delivering exceptional strength, abrasion resistance, and structural stability.

• Enhanced softness and uniformity The dual-layer configuration offers improved surface smoothness, fiber consistency, and overall fabric integrity.

• High-purity polypropylene Ensures safe contact with skin, making SS suitable for medical and hygiene products.

Manufacturing Process

D-TEX SS nonwoven is manufactured using an advanced dual-spunbond extrusion and thermal bonding process, ensuring:

• Uniform fiber fineness and web formation

• Stable double-layer bonding strength

• High production cleanliness & low linting

• Precise control of basis weight

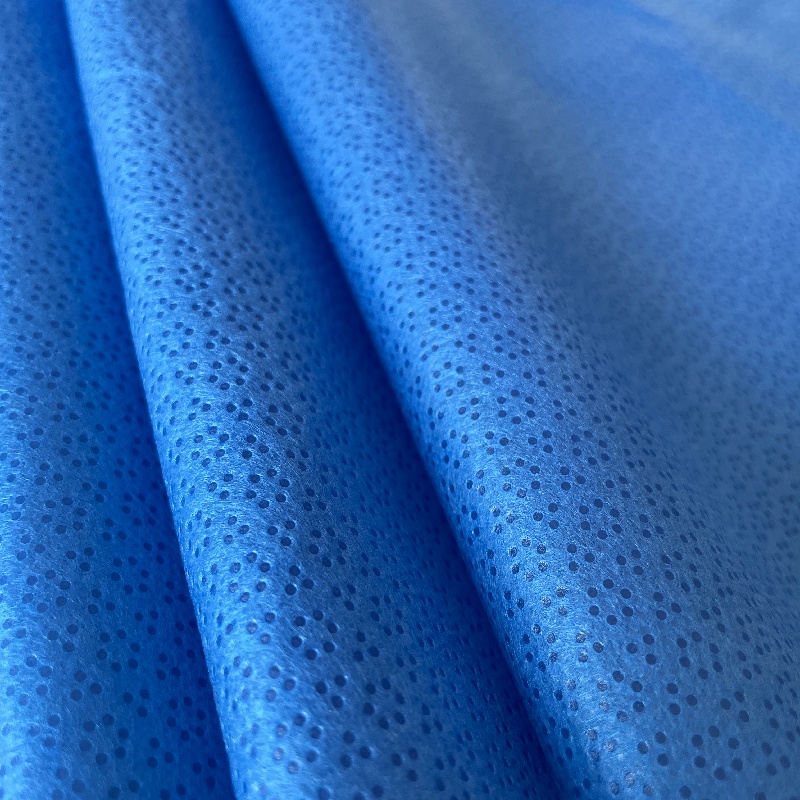

• Consistent fabric appearance and surface texture

Our production lines follow strict quality control standards to meet global customer requirements for reliability and consistency.

Key Features & Advantages

• High Strength & Durability Dual spunbond layers provide enhanced mechanical performance for demanding applications.

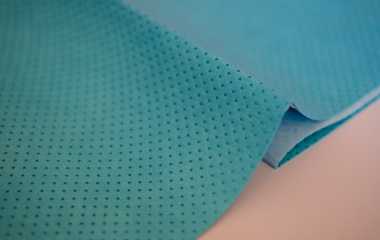

• Soft & Comfortable Hand Feel Smooth surface suitable for personal care and skin-contact uses.

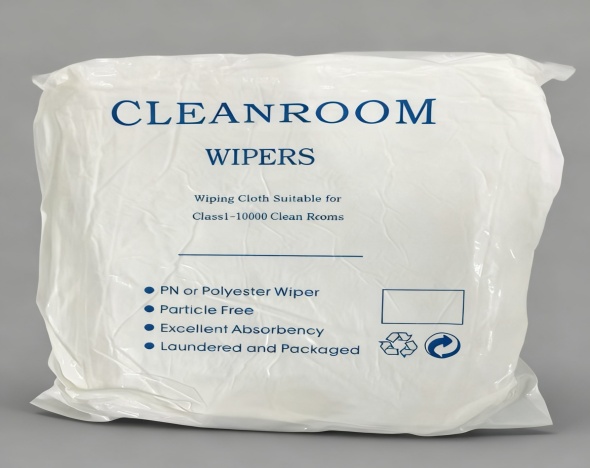

• Low Lint & Clean Processing Ideal for medical drapes, hygiene products, and controlled environments.

• Excellent Uniformity Stable fiber distribution improves product performance and processing efficiency.

• Customizable Options Weight, width, color, and functional treatments (anti-static, hydrophilic, UV-resistant, etc.) available on demand.

Typical Applications

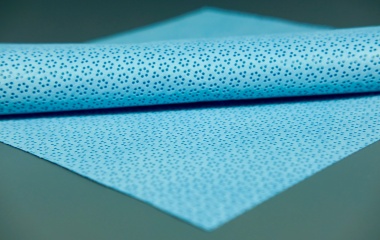

Medical & Hygiene

• Surgical masks (outer/inner layers)

• Disposable medical sheets

• Sanitary napkin topsheets

• Baby diaper backsheet or topsheet

Industrial & Protective

• Protective packaging

• Industrial wipes

• Coverall outer layers

Household & Consumer Goods

• Shopping bags

• Agriculture crop covers

• Laminated fabric substrates

Technical Specifications (Customizable)

• Material: Polypropylene (100% PP)

• Structure: SS (Spunbond–Spunbond)

• Basis Weight: 10–100 gsm

• Width: Customizable

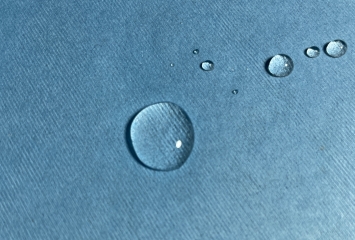

• Surface Treatment: Hydrophilic / Hydrophobic / Anti-static / UV-resistant / Printable grade